A watch’s mainspring is a crucial component of its mechanical movement, providing the necessary power to drive the timekeeping mechanism. It’s a coiled spring made of a special alloy, typically steel or a composite material, with excellent elasticity properties.

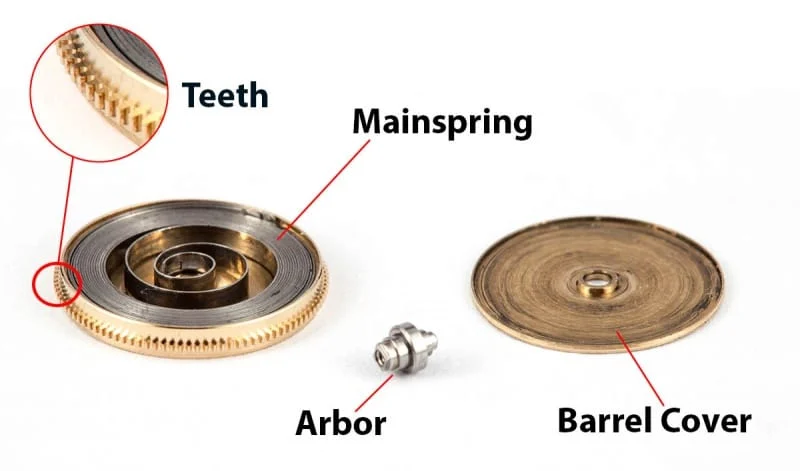

The mainspring is housed in a cylindrical barrel, and one end of the spring is attached to the barrel while the other end is fixed to the watch’s gear train. When the mainspring is wound, either manually or through an automatic winding system, potential energy is stored in the coiled spring.

As the mainspring unwinds, it releases the stored energy gradually, transmitting power through the gear train. The gear train consists of a series of gears that transfer the rotational energy from the mainspring to the escapement mechanism. The escapement regulates the release of this energy in precise increments, enabling the movement’s timekeeping functions.

The unwinding mainspring exerts torque on the gear train, causing the gears to rotate and transmit power to various components of the movement. This includes the balance wheel, which oscillates back and forth, and the escapement mechanism, which controls the rate at which the energy is released.

The mainspring’s torque diminishes as it unwinds, affecting the amplitude of the balance wheel’s oscillations. To maintain accurate timekeeping, watchmakers utilize various mechanisms, such as a fusee or a constant-force mechanism, to counteract the decreasing torque and ensure consistent power delivery to the escapement throughout the mainspring’s unwinding cycle.

In summary, a watch’s mainspring functions as an energy storage device, converting the manual or automatic winding into potential energy. This energy is then released gradually to power the movement’s various components, ensuring accurate timekeeping.

Custom FAE Mechanical Watch – Made in USA

For the pragmatic yet discerning watch owner, FAE offer the “Sapphire” edition of the Field Mechanical Watch which features all possible upgrades.